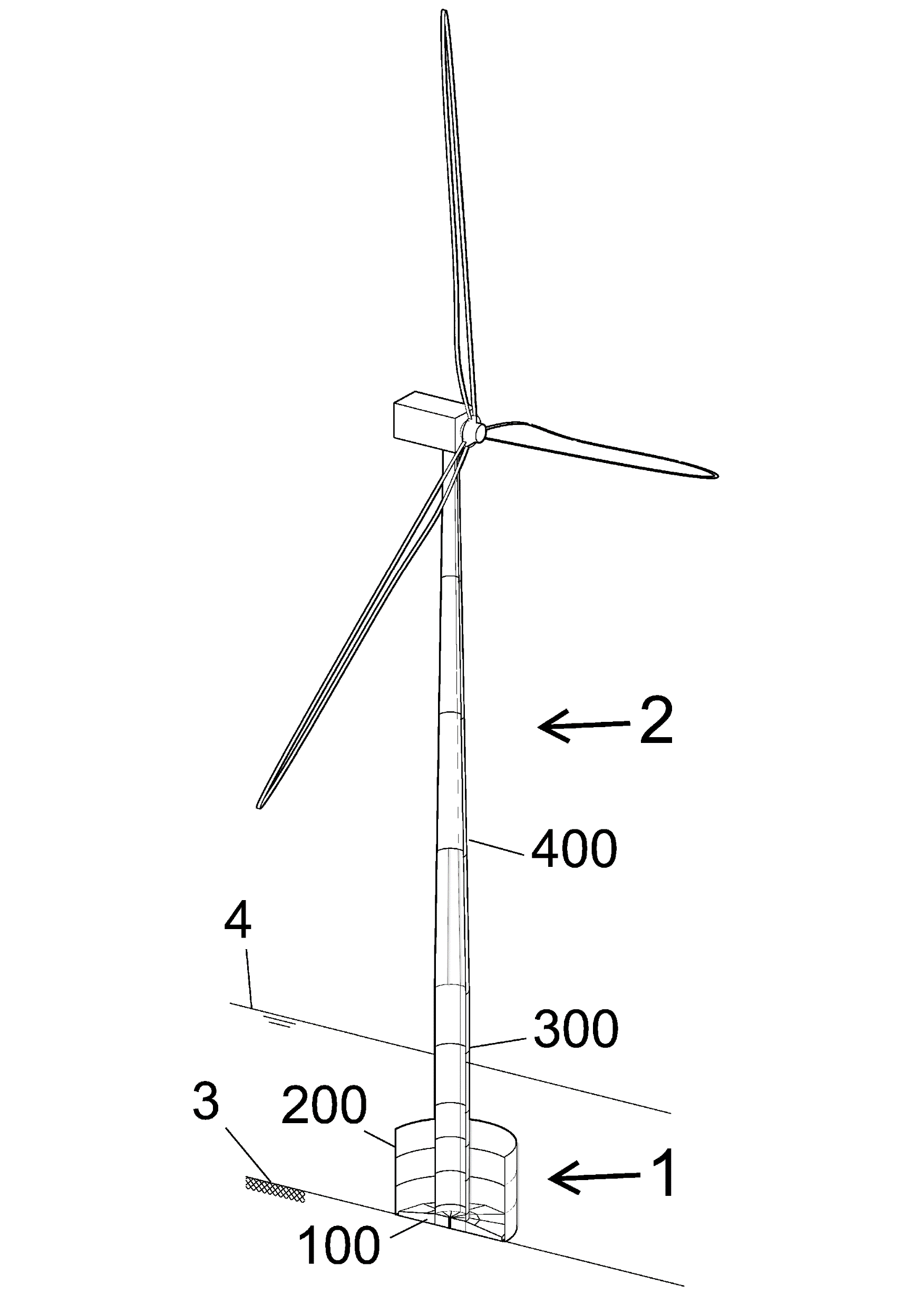

EcoGBF at a glance

An Economical/Ecological steel Gravity-Based Foundation (<1 €/W)

Utilizing the proven concept of gravity bases

Composed of three components: a base structure [100], a shaft [300] and an independent ballast confiner [200]

Efficient use of steel solely for load carrying structure

Economical and light, also for transportation & installation:

7 MW OWT @30 m water depth: 1200 T, ~6 M€

20 MW OWT@50 m water depth: 3200 T, ~13 M€

Exploiting the fabrication experience of shipbuilders, bridge fabricators, monopile manufacturers, and storage tank manufacturers

Ballast from local sand, gravel or demolished concrete

Eco-friendly, can function as an artificial reef to preserve and restore marine ecosystem

Advantages of EcoGBF

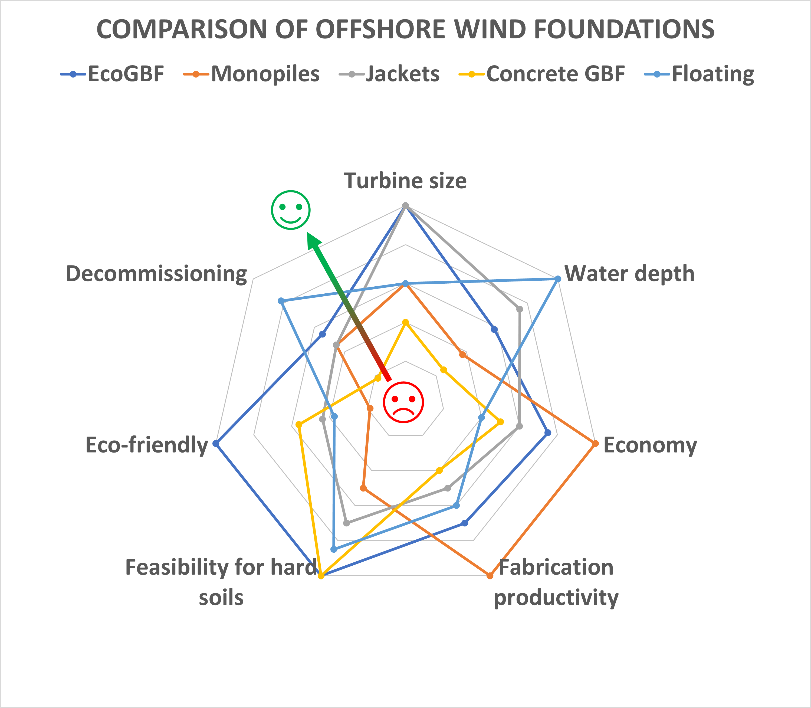

Feasible for large turbines (>15 MW, cf. monopiles)

Economical @30-70 m water depth (cf. jacket, GBF)

Reduced craneage for T&I, feasible afloat T&I

Promote biodiversity in the marine ecosystem

Noise-free installation

Sustainable, easy decommissioning, fully recyclable

Viable for hard seabed even at shallow waters

Short fabrication time by industrialized production

Serial fabrication; ~50% of supply chain out of OWI

No need for deep ports or strong quays

TP-less, shop installation of secondary steels

Application for temporary installations

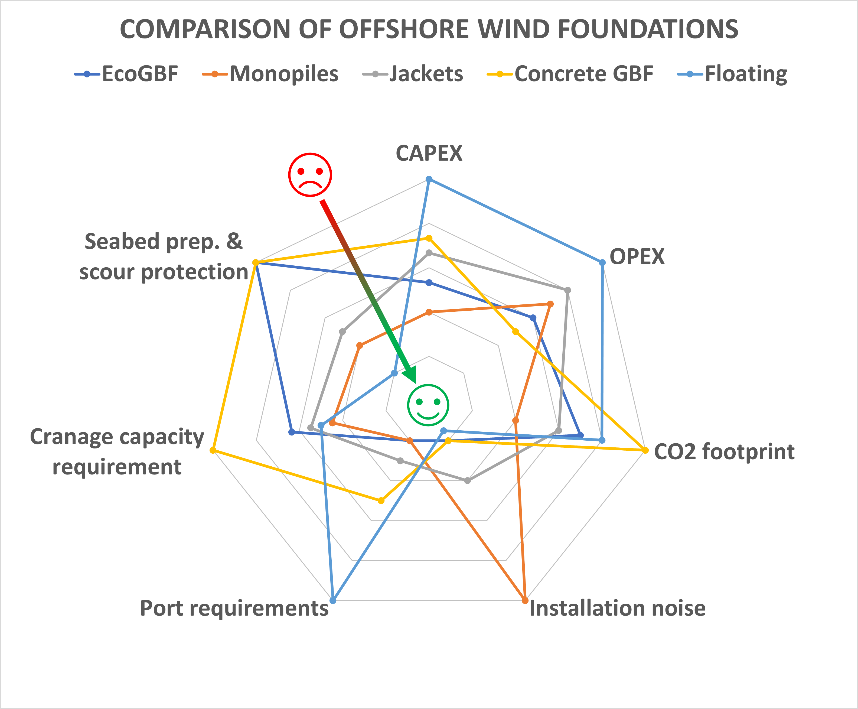

Comparsion of EcoGBF with other foundations

Benefits of EcoGBF following the UN SDGs

Outlook

- Completion of detailed studies and lab tests (2023-24)

- Prototype tests (2024-26)